We are your trusted partner in the home textiles industry and supply high-quality primary resources for the production of textile goods.

learn more

At ALTEX, we aim at making a positive impact on resource preservation by recycling textile waste. As a supplier of high-quality primary resources or shredded fibres, we supply various industries – such as the home textile, automotive, equestrian and spinning industries – with our products.

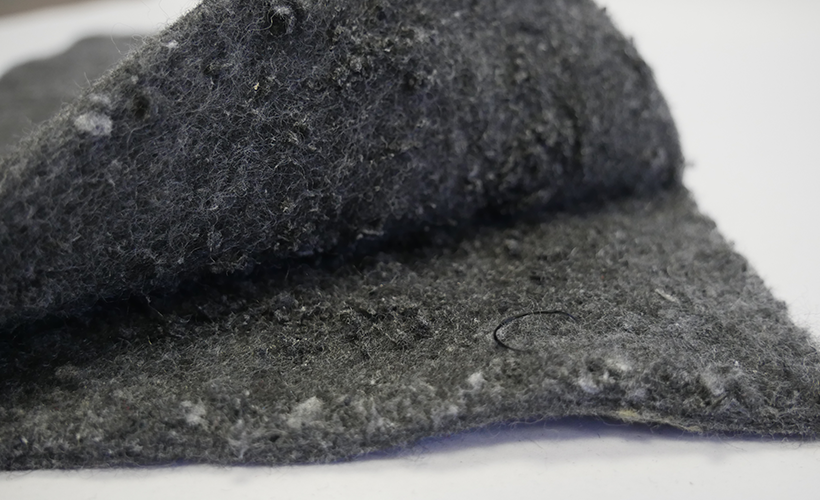

Our products are recycled textile fibres, so-called shredded fibres, which are obtained from all textile waste and come in various forms and compositions.

The textile remnants include waste from production as well as products that have already been used, such as carpets or clothing. The scraps are processed into precious fibres using cutting-edge Laroche tearing systems. This mechanical process requires no chemical additives and produces zero water pollution – an environmentally friendly and sustainable method that is highly efficient. Our products also include blends of torn fibres with original fibres and short fibres obtained by grinding torn fibres.

To enhance certain fibre attributes, we either blend original fibres with different recycled fibres or different recycled fibres with each other. We also offer original fibres. These allow us to provide fibres meeting the specific requirements of our customers. We treat the blends with anti-mold and flame retardants as well as anti-static agents to ensure the durability of our fibres. While the use of flame retardants in fibres is particularly important for the automotive industry, the home textiles industry benefits more from mold-resistant fibres.

When recycled torn fibres are ground by special machines to a length of up to 3 mm, so-called short fibres are produced. These are often used in the wetlaid process – a technique for producing particularly fine nonwovens.

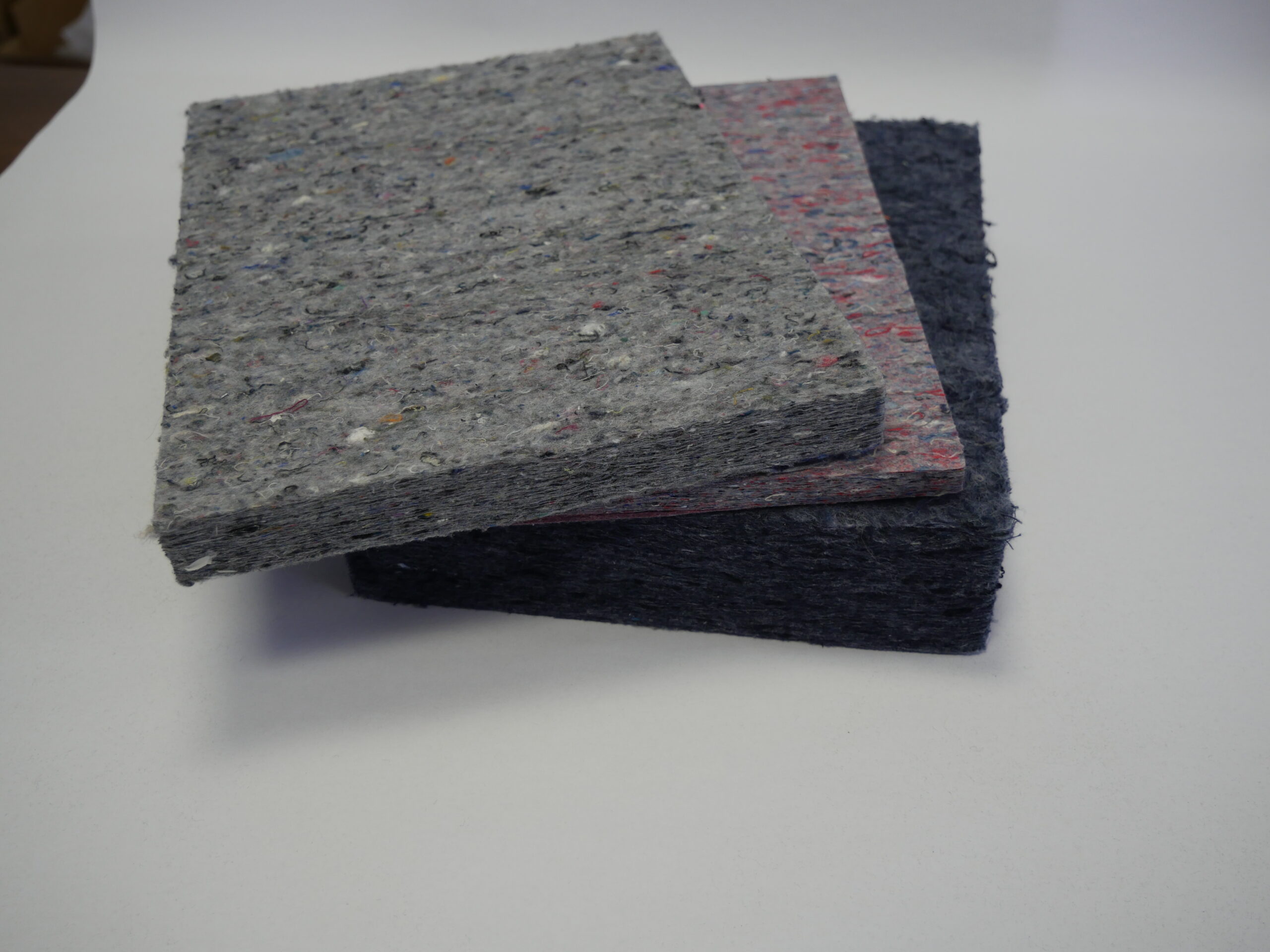

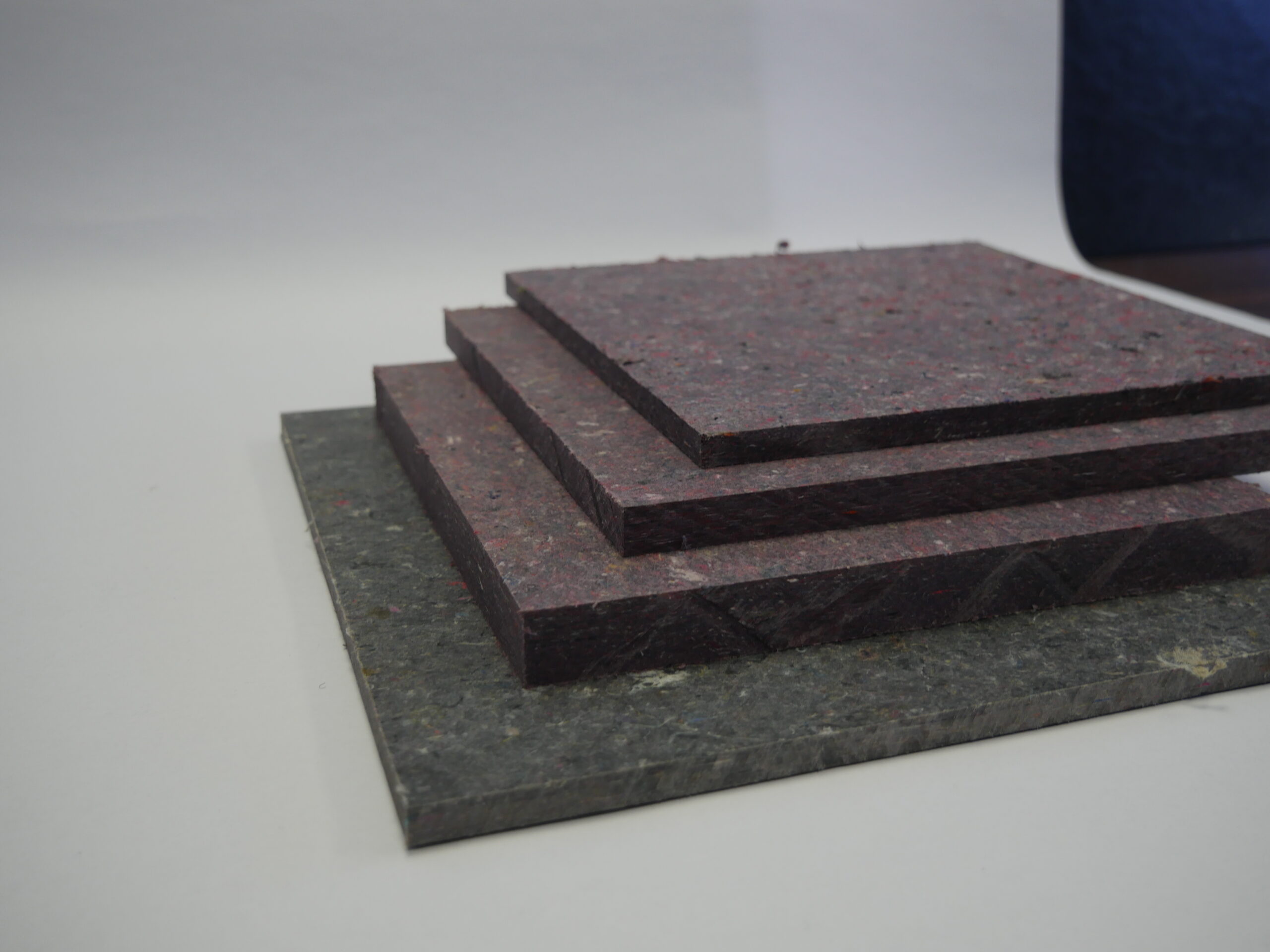

Nonwovens made from discarded textiles are a key product of textile recycling. These fabrics are used in various industries, particularly the electrical and textile industries, as they can be tailored to individual requirements. In this way, we make an active contribution to the circular economy and offer our customers a sustainable solution with technical performance.

We manufacture semi-finished textile products – materials that are not yet final goods, but are prepared precisely for this purpose. Our semi-finished products are further processed by other companies and are used where insulation, padding, lamination or reinforcement is desired.

Our shreds are more than just shredded fibers – they form the link between old textile materials and innovative industrial products. Through an effective and precise treatment process, we transform old materials into versatile raw materials that are given a second chance in the form of nonwovens, insulation or upholstery. They are often used in the riding arena industry to ensure the stability of the ground and thus the safety of the animals.

We are always happy to answer your questions. Simply use our contact form to get in touch with us – we will reply as quickly as possible.

To the contact form